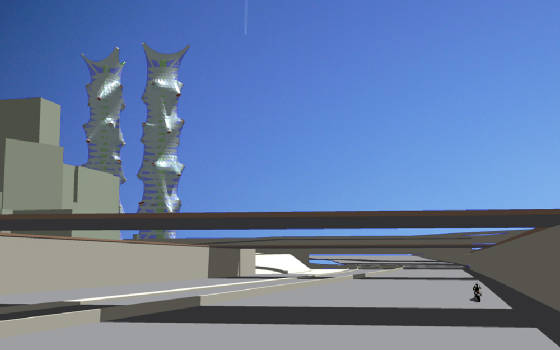

The proposed

Fantastic Elastic Thermo-Plastic Tensegrity Tube Tower (FETP3).

The proposed

Fantastic Elastic Thermo-Plastic Tensegrity Tube Tower (FETP3).

Work with membrane tensegrity structures, specifically with elongated tube structures,

has been ongoing for quite some time, but the recent development of a fully parametric model in Rhino+Grasshopper will lead

to the fabrication of large scale protorypes soon. We'll keep you posted!

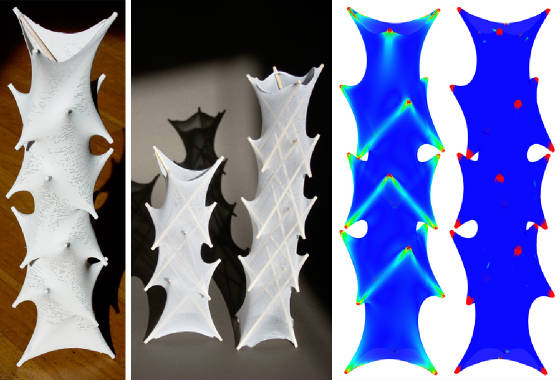

Small

scale stretch fabric models demonstrating structural feasibility + mean curvature (blue indicates a mean curvature approaching

zero) and Gaussian curvature (blue indicates -.001 to -35) analyses of a computationally derived membrane.

Small

scale stretch fabric models demonstrating structural feasibility + mean curvature (blue indicates a mean curvature approaching

zero) and Gaussian curvature (blue indicates -.001 to -35) analyses of a computationally derived membrane.

In a membrane tensegrity system, a structural

membrane replaces the tendons utilized in a typical tensegrity structure. The in-plane tensile forces of the membrane are

in equilibrium with the axial forces of the compression struts, and the two discreet sets of elements support eachother. I

have developed a multi-tiered tube system, using 3 to 5 compression struts per tier (as physical models, for the most part)

inside a continuous sheath to create vertical structures.

Tensegrity

tube towers from Boston's I-90.